-

Into KDTThe company's headquarters and software R&D center are located in Guangzhou Economic and Technological Development Zone, with R&D institutions in Italy and South Korea, and production bases in Rimini, Italy and Chengdu, Sichu

-

Products

-

-

-

Investor

Esperanto

Esperanto

Shqiptare

Shqiptare

España

España

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Afrikaans

Afrikaans

Daily maintenance of Edge Bander

Release Time:

2024-02-28 09:25

Source:

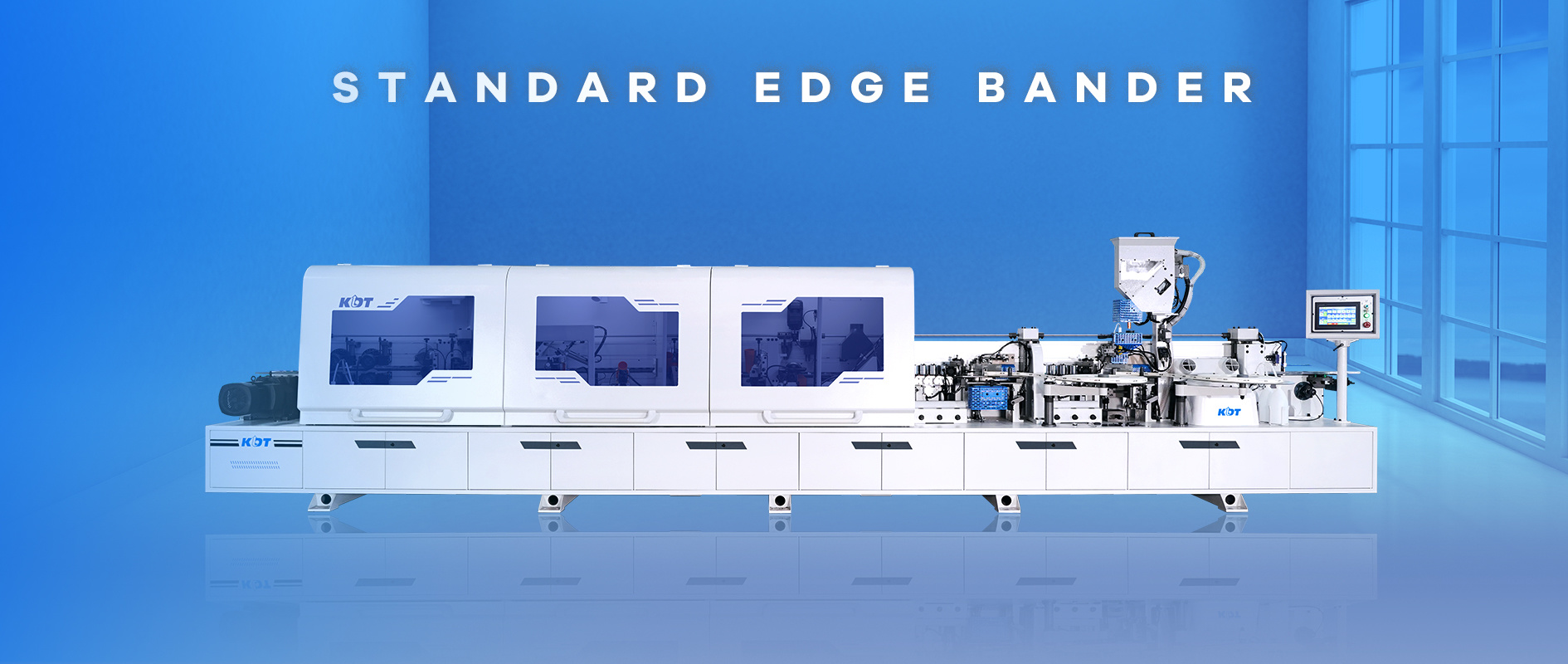

In industrial production, Edge Bander is a commonly used equipment used to process the edges of furniture, doors, windows and other products. In order to ensure the normal operation of Edge Bander and extend the service life of the equipment, routine maintenance is crucial. The following are some daily maintenance methods for Edge Bander:

Cleaning and maintenance:

Regularly clean key components such as the Edge Bander's work surface, conveyor belt, and cutter to ensure that no dust, chips, and other debris affect the normal operation of the equipment. Use detergent and a soft cloth to clean, and avoid using highly corrosive chemicals.

Lubrication and maintenance:

The various sliding parts and bearings of Edge Bander require regular lubrication and maintenance to reduce wear and friction and ensure smooth operation of the equipment. Use an appropriate amount of lubricating oil or grease for lubrication, being careful not to drip excessively.

Tool replacement:

Edge Bander's cutting tools are important processing components, so the wear of the cutting tools needs to be checked regularly and seriously worn tools need to be replaced in a timely manner to ensure the processing effect and workpiece quality.

Parameter adjustment:

Regularly check the processing parameters of Edge Bander, including speed, temperature, pressure and other set values, to see if they meet the requirements. If necessary, adjust the corresponding parameters to ensure processing quality and efficiency.

Fastener inspection:

Regularly check whether the connecting fasteners of the Edge Bander are loose. If any looseness is found, tighten them in time to ensure that the equipment is stable and reliable during operation.

Quality inspection:

Regularly conduct quality inspections on products processed by Edge Bander to check whether the edge sealing effect, dimensional accuracy and other indicators meet the requirements, and adjust equipment parameters or maintain components in a timely manner to ensure product quality.

Related News

undefined

Hotline: 0086-400-8853-553

Phone: 0086-400-9900-083

Mail: sales@kdtmac.com

Scan to follow us

Scan to follow us

Message