-

Into KDTThe company's headquarters and software R&D center are located in Guangzhou Economic and Technological Development Zone, with R&D institutions in Italy and South Korea, and production bases in Rimini, Italy and Chengdu, Sichu

-

Products

-

-

-

Investor

Esperanto

Esperanto

Shqiptare

Shqiptare

España

España

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Afrikaans

Afrikaans

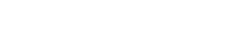

"EDGE BANDER FOR DOORS" in modern industry: a powerful tool to improve furniture manufacturing efficiency

Release Time:

2024-01-31 09:40

Source:

With the continuous development of furniture manufacturing technology, EDGE BANDER FOR DOORS, as an important automation equipment, has become a sharp tool in the modern furniture manufacturing industry. This article will introduce the definition and working principle of EDGE BANDER FOR DOORS, as well as its role and advantages in furniture manufacturing.

As an indispensable item in people's daily lives, the manufacturing process of furniture has always been a key area in the industrial field. With the development of technology and changes in market demand, the furniture manufacturing industry is constantly exploring innovative ways to improve production efficiency, reduce costs, and provide higher quality products. As a key automation equipment, EDGE BANDER FOR DOORS is playing an important role in the furniture manufacturing industry.

The definition and working principle of EDGE BANDER FOR DOORS

EDGE BANDER FOR DOORS, also known as edge sealing machine or edge sealing equipment, its main function is to bond sheet materials (such as PVC, ABS, etc.) to the edges of furniture panels through heating and pressure, thereby effectively protecting and strengthening the edges of the panels. Overall aesthetics and durability.

The working principle of EDGE BANDER FOR DOORS can be simply summarized into the following steps:

Plate feeding: Feed the plates to be processed into the machine;

Cutting the edgeband: The EDGE BANDER FOR DOORS cuts the edgeband to the corresponding size according to the required length through the cutting device;

Glue the side tape: The side tape passes through the sol device and is coated with a layer of glue to enhance its adhesion to the board;

Adhesion and pressing: The plate and the edge strip are preheated by the heating device, and then pressed by the pressure device to make the edge strip and the plate tightly bonded;

Cooling cutting: After the bonding is completed, the plate and edge strip enter the cooling zone for cooling, and are trimmed and cut by the cutting device.

The role and advantages of EDGE BANDER FOR DOORS in furniture manufacturing

Improved efficiency: The automated features of the EDGE BANDER FOR DOORS make the furniture manufacturing process more efficient, enabling rapid edgeband processing and bonding. Compared with manual edgeband processing, EDGE BANDER FOR DOORS can significantly shorten the manufacturing cycle and improve production efficiency.

Improve quality: The EDGE BANDER FOR DOORS can achieve uniform heating and pressing of the edgeband, ensuring the tight combination of the edgeband and the board, thereby improving the quality and durability of furniture products. Moreover, the cutting and trimming devices of the EDGE BANDER FOR DOORS ensure the consistency of the size and appearance of the edgeband.

Cost savings: The automation features of the EDGE BANDER FOR DOORS reduce the number of operators, thereby reducing labor costs. At the same time, the EDGE BANDER FOR DOORS can also avoid the waste of edgebands and accurately control the amount of edgebands, thereby saving material costs.

Expand the scope of adaptation: The EDGE BANDER FOR DOORS can be adjusted and customized according to different furniture design requirements, and is suitable for many types of panels and edgeband materials. This allows furniture manufacturers to flexibly respond to changes in market demand and expand the scope of product adaptation.

Related News

undefined

Hotline: 0086-400-8853-553

Phone: 0086-400-9900-083

Mail: sales@kdtmac.com

Scan to follow us

Scan to follow us

Message